Head gasket repair is an automotive procedure that stands as a beacon of hope for vehicles facing a critical juncture in their lifespan.

This crucial operation holds the power to revive engines on the verge of failure, potentially sparing car owners from the burden of costly replacements.

In the world of automotive maintenance, few tasks carry as much significance as head gasket repair.

In this article, we will delve into the intricacies of this procedure, understanding what a head gasket is, the reasons it may falter, and the essential steps involved in its repair.

Whether you’re a seasoned mechanic or a concerned car owner, the knowledge and insights shared here will empower you to navigate the realm of head gasket repair with confidence, ensuring your vehicle’s longevity and performance remain steadfast.

Table of Contents

What Is a Head Gasket?

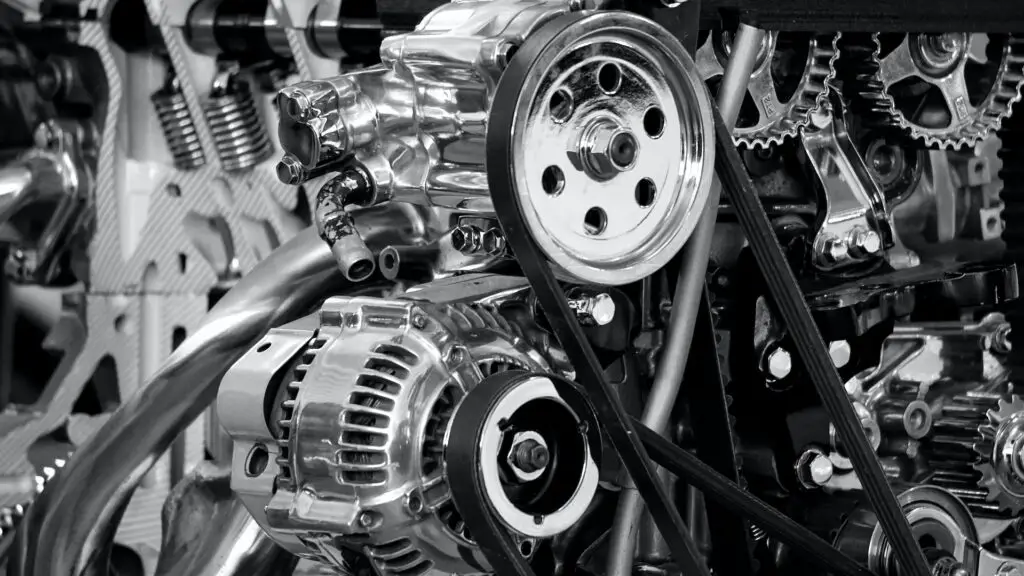

A head gasket is a critical component in an internal combustion engine that plays a crucial role in maintaining the engine’s integrity and efficiency. It is a thin, flat gasket made of materials like metal or composite materials, positioned between the engine block and the cylinder head.

Its primary function is to seal the combustion chambers, ensuring that the high-pressure, hot gases generated during the engine’s operation stay contained within the cylinders.

This seal prevents the mixing of engine coolant and oil with the combustion gases while also maintaining compression within the cylinders. The head gasket must endure extreme temperature and pressure fluctuations, making it susceptible to wear and potential failure.

A damaged head gasket can lead to issues like coolant and oil leaks, reduced engine performance, overheating, and if left unaddressed, catastrophic engine damage.

Therefore, maintaining the integrity of the head gasket is crucial for the overall health and performance of an internal combustion engine.

What Does a Head Gasket Do?

A head gasket serves as a vital component within an internal combustion engine, performing several critical functions. Firstly, it seals the interface between the engine block and the cylinder head, effectively separating the combustion chambers from the engine’s coolant and oil passages.

This prevents the mixing of coolant and oil with the hot, high-pressure gases generated during combustion, ensuring efficient engine operation. Secondly, the head gasket helps maintain the proper compression ratio within the cylinders, essential for generating power and maintaining engine efficiency.

It also aids in dissipating heat from the combustion process to the engine’s cooling system. Given the extreme temperatures and pressures within an engine, a head gasket must remain robust and intact to prevent leaks, overheating, loss of power, and potential engine damage.

In summary, a head gasket is a crucial component that seals separates, and regulates various processes within an internal combustion engine, contributing significantly to its overall performance and reliability.

How Does a Head Gasket Work?

A head gasket works by forming a critical seal between the engine block and the cylinder head in an internal combustion engine. It is typically made of durable materials like metal or composite materials.

The head gasket is carefully positioned to fit precisely between these two major engine components. Its primary function is to seal off the combustion chambers, ensuring that the high-pressure, hot gases produced during combustion remain contained within the cylinders.

At the same time, it prevents the mixing of engine coolant and oil with the combustion gases. This separation of functions is essential for maintaining the engine’s integrity and efficiency.

Additionally, the head gasket helps maintain the proper compression ratio within the cylinders, ensuring that the engine can generate power efficiently.

As the engine operates, the head gasket must endure extreme temperature and pressure variations without losing its sealing properties, making it a critical component for the engine’s reliable and safe performance.

Causes of a Blown Head Gasket

A blown head gasket is a significant and potentially costly issue in an internal combustion engine. It can seriously compromise the smooth operation of your car engine. Additionally, failure to carry out a head gasket repair on time can cause expensive to repair engine damage. Several factors can cause a head gasket to fail. These include:

1. Overheating

Overheating can cause a head gasket to blow due to the extreme temperatures involved. When an engine overheats, the excessive heat can cause the cylinder head and engine block to expand at different rates, putting uneven pressure on the head gasket. This can lead to the head gasket becoming compromised, allowing coolant and combustion gases to escape or mix.

Additionally, the intense heat can weaken and deteriorate the gasket material itself, making it more susceptible to failure. To prevent head gasket damage from overheating, it’s crucial to address cooling system issues promptly and avoid prolonged periods of high engine temperatures.

2. Engine Stress

Engine stress, often caused by modifications like high-performance upgrades or turbocharging, can blow a head gasket by increasing the internal pressure and heat generated in the engine. These modifications can lead to higher levels of cylinder pressure and temperature, placing added strain on the head gasket.

Over time, this increased stress can weaken the gasket, causing it to fail and allowing combustion gases to escape or mix with coolant and oil. To prevent head gasket damage from engine stress, it’s essential to ensure that the gasket and engine components are appropriately designed and reinforced to handle the increased demands of these modifications.

3. Age and Wear

Age and wear can lead to head gasket failure as the gasket undergoes constant cycles of heating and cooling during the engine’s operation. Over time, this thermal stress and exposure to high temperatures can cause the gasket material to deteriorate, lose its flexibility, and develop tiny cracks or weaknesses.

As a result, the gasket may no longer provide a reliable seal between the engine block and cylinder head, allowing coolant and combustion gases to escape or mix. Regular maintenance can help prolong the life of a head gasket, but eventually, even with proper care, the cumulative effects of age and wear can lead to its failure.

4. Poor Maintenance

Poor maintenance can contribute to head gasket failure by allowing contaminants, debris, and corrosive substances to accumulate in the engine. Over time, these deposits can degrade the gasket’s sealing surfaces and create conditions that lead to leaks.

For example, neglecting regular coolant changes can result in the coolant becoming acidic, which can corrode the gasket material and weaken its sealing ability. Similarly, dirty engine oil can introduce abrasive particles that damage the gasket.

Inadequate maintenance can also lead to coolant leaks or overheating, which can further stress the head gasket and increase the risk of failure. Proper maintenance, including routine fluid changes and system inspections, is essential to prevent head gasket problems associated with poor upkeep.

5. Engine Coolant Problems

Engine coolant problems, such as coolant leaks or insufficient coolant levels, can lead to head gasket failure in several ways. When coolant levels are low or when there is a leak, the engine can overheat, causing uneven expansion and contraction of engine components.

This uneven stress can damage the head gasket, compromising its ability to seal the combustion chambers effectively. Additionally, if coolant leaks into the cylinders due to a damaged head gasket, it can lead to a phenomenon known as hydrolock, where liquid coolant prevents the engine from turning over, potentially causing severe damage.

To prevent head gasket issues related to coolant problems, it’s crucial to maintain the cooling system properly, fix any leaks promptly, and ensure the coolant is at the recommended levels and of the correct type.

6. Incorrect Torque

Incorrect torque when installing the cylinder head can result in head gasket failure. When the head bolts are not tightened to the manufacturer’s specified torque settings, it can lead to uneven pressure on the head gasket. This uneven pressure may cause the gasket to distort or fail to create a proper seal between the engine block and cylinder head.

As a result, combustion gases, coolant, or oil can leak past the compromised seal, leading to head gasket problems. To prevent this issue, it’s crucial to follow the manufacturer’s torque specifications and proper tightening sequence when installing a new head gasket or reassembling the engine.

7. Material Defects

Material defects in the head gasket can lead to its failure over time. If the gasket is manufactured with flaws or poor-quality materials, it may not have the necessary durability and resilience to withstand the extreme conditions inside the engine.

These defects can result in premature wear, cracking, or weakening of the gasket, causing it to lose its sealing properties and allowing leaks to occur. To prevent head gasket failure due to material defects, it’s essential to use high-quality gaskets from reputable manufacturers known for producing reliable engine components.

8. Detonation or Pre-ignition

Detonation or pre-ignition, abnormal combustion events where the air-fuel mixture ignites before the spark plug fires, can create high-pressure spikes in the cylinders. These pressure spikes can exert excessive force on the head gasket, potentially causing it to fail. The intense pressure generated during detonation or pre-ignition can compromise the gasket’s sealing ability, leading to leaks of combustion gases, coolant, or oil.

To prevent head gasket damage from detonation or pre-ignition, it’s essential to address the root causes of these issues, such as using the correct octane fuel, ensuring proper ignition timing, and addressing any engine management system problems that may be contributing to these abnormal combustion events.

9. Rust or Corrosion

Rust or corrosion in the engine’s cooling passages or on the head gasket’s surfaces can damage the gasket and lead to leaks. When the gasket’s sealing surfaces or the engine’s cooling passages become corroded or pitted, it can compromise the gasket’s ability to create a tight seal between the cylinder head and engine block.

This can result in coolant or combustion gases escaping, potentially causing head gasket failure. To prevent this, it’s important to maintain the engine’s cooling system properly, use the recommended coolant, and address any corrosion issues promptly to avoid damage to the gasket and other engine components.

10. External Damage

External damage to the engine, such as from accidents or physical impact, can lead to head gasket failure. When the engine sustains external damage, it can cause the cylinder head and engine block to become misaligned or warped. This misalignment or warping can put uneven pressure on the head gasket, compromising its sealing capability.

As a result, coolant or combustion gases may escape or mix, leading to head gasket problems. To prevent head gasket damage from external factors, it’s important to handle the engine carefully and repair any physical damage promptly to ensure proper alignment and sealing.

NOTE: A blown head gasket can result in symptoms like coolant and oil mixing, overheating, white exhaust smoke, loss of power, and engine misfires. If you suspect a blown head gasket, it is crucial to address the issue promptly to prevent further engine damage. Repairing or replacing a head gasket is a complex and labor-intensive task, often requiring the expertise of a professional mechanic.

Symptoms of a Bad Head Gasket

A bad or blown head gasket can manifest various symptoms, and the severity of these symptoms can vary. These symptoms should be the first telltale sign that you need an immediate head gasket repair. Some of the common signs associated with a bad head gasket include:

1. Overheating

Overheating is a common symptom of a bad head gasket because a compromised gasket can allow combustion gases to leak into the engine’s cooling system. These gases can create hot spots within the cooling system, leading to increased engine temperatures. As a result, the engine may consistently run hotter than normal, potentially causing overheating.

This symptom often accompanies other signs like white exhaust smoke, coolant loss, and the presence of air bubbles in the cooling system. Overheating due to a bad head gasket should be addressed promptly to prevent further engine damage.

2. White Exhaust Smoke

White exhaust smoke is a symptom of a bad head gasket because it often indicates the presence of coolant leaking into the combustion chambers. When the head gasket is compromised, coolant can mix with the hot combustion gases, causing it to vaporize and exit the exhaust as white smoke.

This is a clear sign of a coolant leak and a bad head gasket. It’s essential to address this symptom promptly, as continued operation with a leaking head gasket can lead to engine damage.

3. Milky Engine Oil

Milky engine oil is a symptom of a bad head gasket because it suggests that coolant is mixing with the engine oil. When the head gasket is compromised, it can allow coolant to leak into the engine’s oil passages. This coolant contamination results in a milky or foamy appearance of the engine oil on the dipstick or oil filler cap.

The mixing of coolant and oil can reduce the oil’s lubricating properties and potentially lead to engine damage if left unaddressed. Recognizing milky engine oil is an important sign of a head gasket issue and should prompt immediate inspection and repair.

4. Loss of Coolant

A loss of coolant is a common symptom of a bad head gasket because the gasket can develop leaks that allow coolant to escape from the engine’s cooling system. Since the head gasket separates the combustion chambers from the coolant passages, a compromised gasket can permit coolant to leak into the cylinders or out of the engine.

This often results in a noticeable reduction in the coolant level without any visible external leaks. Monitoring the coolant level and addressing unexplained coolant loss is crucial to identify a potential head gasket problem.

5. Bubbles in the Radiator

Bubbles in the radiator or coolant overflow tank are a symptom of a bad head gasket because they indicate the presence of combustion gases in the engine’s cooling system. When the head gasket is compromised, it can allow these gases to escape from the cylinders and enter the coolant passages.

The gases create bubbles when they mix with the coolant, leading to noticeable bubbling or gurgling in the radiator or overflow tank when the engine is running. This symptom suggests a head gasket issue and should be investigated promptly to prevent further damage to the engine.

6. Poor Engine Performance

Poor engine performance is a symptom of a bad head gasket because a compromised gasket can disrupt the combustion process in the engine. Leaking head gaskets can allow coolant or combustion gases to enter the cylinders, affecting the air-fuel mixture and combustion efficiency.

This can result in reduced power, engine misfires, sluggish acceleration, and overall decreased performance. Addressing poor engine performance is crucial, as it not only impacts the vehicle’s drivability but also prevents potential engine damage associated with a bad head gasket.

7. Coolant Leaks

Coolant leaks are a symptom of a bad head gasket because a compromised gasket can allow coolant to escape from the engine. These leaks may manifest as visible coolant puddles under the vehicle or as drips or seepage from the engine.

The head gasket separates the combustion chambers from the coolant passages, so when it fails, it can permit coolant to leak into the engine’s cylinders or out of the engine entirely. Identifying and addressing coolant leaks promptly is essential to prevent engine overheating and further damage associated with a bad head gasket.

8. Spark Plug Issues

Spark plug issues, such as wet or fouled spark plugs, can be a symptom of a bad head gasket. When the head gasket is compromised, it can allow coolant to leak into the combustion chambers. This coolant can then contaminate the spark plugs, making them wet or fouled and hindering their ability to create a spark for ignition.

This can lead to engine misfires, rough idling, and poor combustion, resulting in reduced engine performance. Addressing spark plug issues caused by a bad head gasket typically involves replacing the plugs and repairing the gasket to prevent further damage.

9. Increased Exhaust Pressure

Increased exhaust pressure can be a symptom of a bad head gasket because a compromised gasket may allow combustion gases to escape from the cylinders into the exhaust system.

This can lead to higher-than-normal pressure levels in the exhaust, which may result in symptoms like a louder exhaust noise or visible signs of pressure in the tailpipe, such as smoke or emissions.

Addressing increased exhaust pressure due to a bad head gasket is essential to prevent further engine damage and ensure proper exhaust system function.

10. Rough Idling

Rough idling is a symptom of a bad head gasket because a compromised gasket can lead to uneven combustion in the engine cylinders. This uneven combustion can result in engine misfires and vibrations during idle, causing a rough or erratic idle.

The misfiring cylinders may struggle to maintain a consistent idle speed, leading to noticeable engine performance issues. Addressing rough idling caused by a bad head gasket typically involves gasket replacement to restore proper cylinder sealing and combustion.

NOTE: It’s essential to address these symptoms promptly to prevent further engine damage, as a bad head gasket can lead to severe issues if left untreated. Repairs typically involve replacing the head gasket, which is a complex and labor-intensive process best performed by a professional mechanic.

How to Test for a Blown Head Gasket

Testing for a blown head gasket is essential if you suspect engine issues like overheating, coolant loss, or white exhaust smoke. Below is a step-by-step procedure to help you diagnose a blown head gasket:

Tools and Materials Needed

- Coolant pressure tester or combustion leak test kit

- Safety goggles and gloves

- A clean white cloth or paper towel

Procedure

1. Safety Precautions

- Ensure the engine is cold. Opening a hot radiator or coolant system can lead to burns or injuries.

- Wear safety goggles and gloves to protect yourself from hot fluids and potential chemical exposure.

2. Visual Inspection

- Examine the exterior of the engine for visible coolant leaks. Look for coolant puddles under the vehicle or drips from the engine.

- Check the oil dipstick and oil filler cap for milky or foamy residue, which indicates coolant contamination in the oil.

3. Check Coolant Level

- Ensure the coolant reservoir or radiator is filled to the proper level when the engine is cold. A low coolant level may indicate a leak.

4. Start the Engine

- Start the engine and let it idle. Observe the exhaust pipe for any abnormal emissions, such as white smoke.

5. Coolant Pressure Test

- Allow the engine to cool down completely if it is running.

- Remove the radiator or coolant reservoir cap (if your vehicle has a pressurized reservoir).

- Attach a coolant pressure tester to the radiator or reservoir.

- Pump the tester to pressurize the cooling system. The pressure should remain stable; a drop in pressure could indicate a leak.

6. Combustion Leak Test (Optional)

- If you suspect a head gasket issue but don’t find external leaks, you can perform a combustion leak test.

- Remove the radiator or coolant reservoir cap.

- Use a combustion leak test kit, following the manufacturer’s instructions.

- This test involves placing a chemical solution (provided in the kit) in a test chamber and holding it over the radiator or reservoir opening while the engine runs. The solution changes color if combustion gases are present in the coolant, indicating a blown head gasket.

7. Check Spark Plugs

- Remove the spark plugs one at a time and inspect them.

- Look for signs of coolant or oil contamination on the spark plug electrodes or threads. This can suggest a head gasket issue affecting specific cylinders.

8. Compression Test (Optional)

- If you suspect a localized head gasket issue affecting a specific cylinder, you can perform a compression test.

- Follow the manufacturer’s instructions for the compression tester.

- Compare the compression readings across all cylinders. A significant variation may indicate a problem.

9. Professional Diagnosis

- If you are unable to confirm a head gasket issue with the above tests, or if the symptoms persist, consider seeking a professional diagnosis from a mechanic or automotive technician. They can use more advanced tools like a borescope or perform a cylinder leakage test to pinpoint the issue accurately.

Remember that diagnosing a blown head gasket can be complex, and some symptoms may overlap with other engine problems. If you are uncertain or uncomfortable with any step of the diagnosis, it’s best to consult a professional mechanic for a thorough assessment and repair.

What are the Head Gasket Repair Options?

Repairing a head gasket is a complex and labor-intensive task, often requiring the expertise of a professional mechanic. There are a few different repair options available, depending on the extent of the damage and the condition of the engine. Here are the main head gasket repair options:

1. Head Gasket Replacement

This is the most common and effective repair method for a blown head gasket. It involves removing the cylinder head(s) from the engine to access and replace the damaged gasket.

The repair process typically includes:

- Draining the coolant and engine oil.

- Removing the intake and exhaust manifolds, valve cover(s), timing belt or chain (if applicable), and other components to access the cylinder head(s).

- Loosening and removing the cylinder head bolts.

- Carefully lift off the cylinder head(s) and remove the old gasket.

- Thoroughly cleaning the cylinder head(s) and engine block mating surfaces.

- Installing a new head gasket and torquing the cylinder head bolts to the manufacturer’s specifications.

- Reassembling all components in reverse order.

After the repair, it’s essential to fill the engine with fresh coolant and oil, and then perform a pressure test to ensure there are no additional leaks.

2. Engine Block Sealant/Additives

- Some products on the market claim to seal minor head gasket leaks without disassembling the engine. These are typically liquid sealants or additives that you pour into the radiator or coolant system.

- While these products may temporarily stop minor leaks, they are not a permanent solution and are often considered a temporary fix. They may not work for severe head gasket damage or leaks in critical areas.

- It’s important to follow the manufacturer’s instructions when using these products, and they should be seen as a last resort before considering a complete head gasket replacement.

3. Engine Replacement or Rebuild

- In cases of severe engine damage, where the head gasket failure has led to significant internal damage, a complete engine replacement or rebuild may be necessary.

- An engine replacement involves swapping out the entire engine with a new or refurbished one.

- An engine rebuild entails disassembling the existing engine, repairing or replacing damaged components, and then reassembling it to factory specifications.

- These options are more expensive and time-consuming than head gasket replacement but may be necessary if the engine is extensively damaged.

5. Professional Repair vs. DIY

- Head gasket replacement is a complex job that requires specific tools, knowledge, and experience. It is recommended to have this repair performed by a professional mechanic unless you have advanced automotive repair skills.

- Attempting a DIY head gasket repair, especially for those without the necessary expertise, can lead to costly mistakes and potentially worsen the engine’s condition.

Ultimately, the appropriate head gasket repair option depends on the severity of the damage, the engine’s overall condition, and your budget. Consulting with a qualified mechanic is crucial to assess the extent of the issue and determine the most suitable repair approach.

Head Gasket Repair: A Step-by-Step Procedure

Repairing a head gasket is a complex and labor-intensive process that requires careful attention to detail. This step-by-step procedure assumes that you have the necessary tools, experience, and a replacement head gasket ready for installation. If you’re not comfortable with these steps, it’s highly recommended to seek professional help. Here’s a detailed guide for head gasket repair:

Tools and Materials Needed

- Replacement head gasket

- Torque wrench

- Gasket sealant (if specified by the manufacturer)

- New cylinder head bolts (if recommended)

- Engine coolant and oil

- Socket set and wrenches

- Gasket scraper

- Plastic or wooden scraper

- Rags or shop towels

- Jack and Jack stands

- Timing belt or chain locking tools (if applicable)

- Intake and exhaust manifold gaskets (if necessary)

Procedure

1. Prepare the Vehicle

- Ensure the engine is completely cool before starting any work.

- Disconnect the negative battery terminal to prevent electrical accidents.

- Raise the vehicle using a jack and secure it with jack stands.

2. Drain Coolant and Engine Oil

- Locate the radiator drain plug or remove the lower radiator hose to drain the coolant.

- Drain the engine oil by removing the oil drain plug.

3. Remove Components

- Remove the air intake, throttle body, and other components that obstruct access to the cylinder head.

- If applicable, remove the timing belt or chain according to the manufacturer’s instructions.

- Remove the valve cover(s), exhaust manifold, and intake manifold.

- Disconnect electrical connections, hoses, and brackets as necessary.

4. Loosen Cylinder Head Bolts

- Starting from the center and working outward, gradually loosen the cylinder head bolts in a crisscross pattern. This relieves tension evenly.

5. Remove Cylinder Head

- Carefully lift the cylinder head off the engine block. It may be heavy, so use caution.

- Remove the old head gasket and thoroughly clean the cylinder head and engine block mating surfaces with a gasket scraper or a plastic/wooden scraper.

6. Inspect and Prepare Cylinder Head

- Check the cylinder head for cracks, warping, or other damage. If necessary, have it machined or repaired by a professional.

- Install the new head gasket, ensuring it aligns with all the holes and passages on the cylinder head and engine block.

7. Reassemble Components

- Reinstall the cylinder head, ensuring the gasket is properly positioned.

- Tighten the cylinder head bolts in the manufacturer’s specified torque sequence and to the recommended torque specification using a torque wrench.

- Reassemble all components removed earlier, including manifolds, belts, hoses, and electrical connections.

8. Refill Coolant and Engine Oil

- Refill the cooling system with fresh coolant, and ensure the coolant level is correct.

- Refill the engine with the appropriate oil and replace the oil filter.

9. Pressure Test and Final Checks

- Perform a pressure test to check for coolant leaks or any other issues.

- Reconnect the battery, start the engine, and check for any unusual noises, leaks, or warning lights.

10. Test Drive and Monitor

- Take the vehicle for a test drive to ensure it operates smoothly without overheating.

- Monitor the engine for several days to confirm that there are no coolant, oil, or compression-related issues.

Properly replacing a head gasket is a complex task that requires precision and attention to detail. If you are unsure of your abilities or don’t have the necessary tools, it is highly recommended to have the repair performed by a professional mechanic to ensure the job is done correctly and to prevent potential engine damage.

How Much Does a Head Gasket Repair Cost?

The cost of a head gasket repair can vary widely depending on several factors, including the make and model of your vehicle, the extent of the damage, and where you have the repair done. Some cost considerations include:

- Vehicle Make and Model: Luxury or high-performance vehicles may have more complex engines and require more expensive parts, increasing the cost of the repair.

- Extent of Damage: The severity of the head gasket damage and whether it has caused additional engine damage can significantly impact the cost. If the engine has sustained significant harm, the repair cost may rise substantially.

- Labor Costs: Labor costs can vary based on the location of the repair shop, their hourly rates, and the level of expertise of the mechanics. Dealerships and specialized repair shops may charge higher labor rates than independent mechanics.

- Replacement Parts: The cost of a head gasket itself can vary depending on the vehicle’s make and model. In some cases, it may be necessary to replace other components like cylinder head bolts, which can add to the overall cost.

- Additional Repairs: Sometimes, during a head gasket repair, it’s advisable to replace other related components, such as the timing belt or water pump, which can increase the cost.

- Geographic Location: Labor rates and the overall cost of living can differ significantly from one region to another, impacting repair costs.

Head gasket repair can range from $1,000 to $2,500 or more, with luxury or high-performance vehicles potentially exceeding this range. It’s essential to obtain multiple quotes from reputable mechanics or repair shops to get a more accurate estimate based on your specific vehicle and situation. Keep in mind that in addition to the repair cost, you should budget for coolant, engine oil, and other fluids that will be replaced during the repair process.

How Can You Conduct a Head Gasket Repair Without Replacing It?

Conducting a head gasket repair without replacing it is generally not a recommended practice, as a damaged head gasket typically requires replacement for a lasting and reliable fix. However, in some cases, you may attempt a temporary repair to stop minor leaks while you arrange for a proper head gasket replacement. Here’s a procedure for a temporary repair using a head gasket sealer:

Tools and Materials Needed

- Head gasket sealer (follow the manufacturer’s instructions)

- Coolant and engine oil (if necessary)

- Socket set and wrenches

- Rags or shop towels

Procedure

1. Safety Precautions

- Ensure the engine is completely cool before starting any work.

- Disconnect the vehicle’s battery to prevent electrical accidents.

- Park the vehicle in a well-ventilated area.

2. Identify the Leak

- Locate the source of the head gasket leak. This may involve inspecting the exterior of the engine for visible coolant leaks or checking for signs of coolant contamination in the oil or exhaust.

3. Drain Coolant and Engine Oil (If Necessary)

- If coolant or oil is contaminated, drain and properly dispose of the affected fluids.

4. Follow the Sealer Instructions

- Purchase a reputable head gasket sealer, and carefully follow the manufacturer’s instructions on how to use it. These instructions can vary depending on the product.

5. Prepare the Engine

- Ensure the engine is at its lowest operating temperature. You may need to run it until it reaches normal operating temperature and then let it cool down.

6. Add the Sealer

- Pour the recommended amount of the head gasket sealer into the radiator or coolant reservoir, as specified by the product instructions.

7. Run the Engine

- Start the engine and allow it to idle for the recommended time as specified by the sealer instructions. This usually involves running the engine for a specified period to allow the sealer to circulate and seal any minor leaks.

8. Monitor for Improvement

- Observe the vehicle for a reduction in symptoms like coolant loss, white exhaust smoke, or overheating. Keep in mind that this is a temporary fix and may not work for all head gasket issues.

9. Refill Coolant and Engine Oil (If Necessary)

- If you drained the coolant or oil earlier, refill the engine with the appropriate fluids.

10. Regular Inspection

- Periodically check for signs of improvement or any recurrence of symptoms. Be prepared for the possibility that the temporary repair may only provide short-term relief.

It’s important to emphasize that head gasket sealers are not a permanent solution, and their effectiveness can vary. They are meant for minor leaks and should be seen as a temporary fix until a proper head gasket replacement can be performed. Additionally, some head gasket sealers can leave a residue that may complicate future repairs, so consult a professional mechanic for a permanent solution.

FAQs

How Long Does a Head Gasket Repair Take?

A head gasket repair is a complex and labor-intensive process that can take varying amounts of time depending on several factors. On average, it typically requires 6 to 12 hours of labor. The specific duration depends on factors like the make and model of the vehicle, the extent of the damage, the mechanic’s experience, and the availability of replacement parts.

Vehicles with more complex engine configurations may require additional time, as can cases where the head gasket failure has caused significant engine damage. Additionally, skilled and experienced mechanics tend to complete the repair more efficiently.

The availability of replacement parts and whether any additional components like the timing belt or water pump need replacement also factor into the repair time. To get an accurate estimate, it’s best to consult with a qualified mechanic who can assess your vehicle’s condition and provide a detailed timeline for the repair.

How Long Does a Head Gasket Last?

The lifespan of a head gasket can vary significantly depending on several factors, including the vehicle’s make and model, driving conditions, and maintenance practices. On average, a well-maintained head gasket can last anywhere from 100,000 to 200,000 miles or more.

However, in some cases, head gaskets may fail prematurely due to factors like overheating, poor maintenance, engine modifications, or manufacturing defects. Regular maintenance, including timely coolant changes and proper cooling system care, can help prolong the life of a head gasket and reduce the risk of premature failure.

How Can You Make Your Head Gasket Last Longer?

To maximize the longevity of your head gasket, it’s essential to prioritize regular maintenance and adopt cautious driving habits. Begin by adhering to your vehicle manufacturer’s recommended maintenance schedule, which includes routine coolant and oil changes, as well as comprehensive engine inspections.

Ensure the cooling system is in top condition, replacing aging components like hoses and thermostats. Prevent engine overheating by promptly addressing any cooling system issues. Choose the appropriate engine oil viscosity, maintain proper oil levels, and use high-quality oil to protect the head gasket and engine components.

Practice gentle driving habits to reduce engine strain, avoiding rapid acceleration, abrupt stops, and excessive revving. Regularly inspect for coolant or oil leaks, adhere to torque specifications during repairs, and use the correct octane-rated fuel.

By following these comprehensive measures, you can significantly increase the head gasket’s lifespan and enjoy a trouble-free engine for longer periods.

Do Head Gasket Sealants Work?

Head gasket sealants, also known as “miracle in a can” products, are designed to temporarily seal minor head gasket leaks without the need for a full gasket replacement. While they may provide a short-term fix for small leaks, they are generally considered a temporary solution and not a permanent repair.

The effectiveness of these sealants can vary, and they may not work for severe head gasket damage or leaks in critical areas.

Additionally, using sealants can make future repairs more challenging, as the residue left behind can complicate the gasket replacement process. It’s advisable to consult a professional mechanic for a proper head gasket repair, especially if the damage is significant or persistent.

Can You Drive Your Vehicle with a Blown Head Gasket?

Driving a vehicle with a blown head gasket is not recommended. A compromised head gasket can lead to serious engine problems, including overheating, coolant and oil mixing, loss of engine power, and potential further engine damage.

Continuing to drive with a blown head gasket can escalate the repair costs and potentially result in engine failure, leaving you stranded on the road. It’s safer and more cost-effective to address a head gasket issue promptly, have the necessary repairs performed by a qualified mechanic, and avoid driving the vehicle until it’s in proper working condition again.

Is a Head Gasket Repair Worth It?

Whether a head gasket repair is worth it depends on several factors, including the vehicle’s overall condition, its value, and the extent of the damage. In many cases, repairing a blown head gasket is worth the investment, especially if the vehicle is in good shape otherwise and has sentimental or financial value.

A properly repaired head gasket can extend the life of the vehicle and prevent more costly engine damage.

However, if the vehicle is in poor condition, has multiple mechanical issues, or the repair cost approaches or exceeds the vehicle’s value, it may not be financially viable to proceed with the repair. In such cases, it might be more practical to consider alternative options, such as selling the vehicle or exploring a replacement.

How Do You Replace a Head Gasket?

Replacing a head gasket is a complex and labor-intensive process that involves several steps. Here’s a condensed overview: Start by disconnecting the battery and draining the engine oil and coolant. Remove various components, including the intake and exhaust manifolds, valve cover, and timing belt or chain (if applicable).

Loosen and remove the cylinder head bolts, then carefully lift off the cylinder head, exposing the old gasket. Inspect the cylinder head for damage and prepare it for the new gasket. Install the new head gasket, ensuring it aligns correctly. Reassemble components, tighten the head bolts to the manufacturer’s specs in the specified sequence, and refill with fresh coolant and oil.

Finally, pressure test for leaks and monitor the engine’s performance for a few days. Always consult your vehicle’s repair manual for specific instructions and torque values. If unsure, seek professional help, as improper installation can lead to engine damage.

What Other Parts Should You Fix or Replace During a Head Gasket Repair?

During a head gasket repair, it’s advisable to inspect, service, or replace several other critical components to ensure the engine’s long-term reliability. These include cylinder head bolts, which are often replaced to guarantee proper torque and sealing.

The timing belt or chain is another key consideration; if it’s nearing the manufacturer’s recommended replacement interval, it should be changed since it’s typically accessed during the repair.

Additionally, valve seals, guides, springs, and lifters may be inspected or replaced as needed for improved performance. Intake and exhaust manifold gaskets should also be checked and replaced to prevent future leaks.

Other components such as coolant hoses, thermostats, radiator caps, and water pumps may need attention based on their condition and maintenance history. A comprehensive inspection by a professional mechanic helps identify the specific parts requiring repair or replacement to ensure the engine’s overall health and longevity.

The Conclusion

In conclusion, head gasket repair is a critical and complex undertaking that requires careful attention and expertise. The head gasket serves as a vital seal between the engine block and the cylinder head, ensuring the proper functioning of the engine.

When it fails, it can lead to a range of issues, from overheating to coolant and oil mixing, and even engine damage. Addressing head gasket problems promptly is crucial to prevent further harm and costly repairs.

Whether you’re considering a DIY repair or seeking the assistance of a professional mechanic, understanding the causes, symptoms, and repair process is essential.

Regular maintenance, proper cooling system care, and cautious driving habits can also contribute to prolonging the head gasket’s lifespan. Ultimately, maintaining a well-functioning head gasket is key to ensuring the longevity and reliability of your vehicle’s engine.

Hi, I’m Maurice Nyangano. A certified auto expert who has been in the business for over fifteen years and has worked as a service writer for five years. I take great satisfaction in providing factual information in my buyer’s guides, comparisons, expert repair guides, and car reviews. I write automotive blogs to assist fellow auto experts and car owners in troubleshooting various car issues and offering fixes.